Many medium-sized companies organise their value-added chain across borders, by founding their own production plant abroad. The main reason is competitiveness – which is primarily achieved by reducing labour costs. To ensure that business processes can be mapped across the organisation, and internal functions such as the use of common master data are possible, the companies take advantage of the synergies of the ERP system (ERP: Enterprise Resource Planning). This includes the areas of procurement, logistics, finance and sales. The project for the implementation of the production module at A&R Manufacturing (PLC) Ltd. in Sri Lanka was carried out within the framework of a Bachelor’s thesis.

The Production module

Traditional ERP systems focus on a company’s resource planning and rarely specialise in production planning and control functions. The Microsoft Dynamics NAV 2015 ERP system is geared towards medium-sized enterprises, offering complete integration of all business processes, including a production module with order monitoring.

Necessity of order monitoring

By monitoring orders, the production module ensures that goods in the production stages are recorded – and helps to plan, manage, control and execute all processes required for production.

Collecting operating data

Order monitoring is based on the reporting of operating data documenting the status of processing resp. the order progress that is recorded on a booking data sheet (actual data). This is also where the availability of resources (for departments, work groups and jobs) is shown. In addition, data for production planning can be stored in the system environment, e.g. the target time for the termination of an order or the target consumption amount for a cycle.

Documentation

Microsoft Dynamics NAV offers different ways to present and evaluate data, and also provides information on the order progress while a production order is being executed.

Conclusion

To ensure that medium-sized companies are successful in organising their value-added chain, the production module should also be focused on. It is the basis for successful and realistic production planning and control.

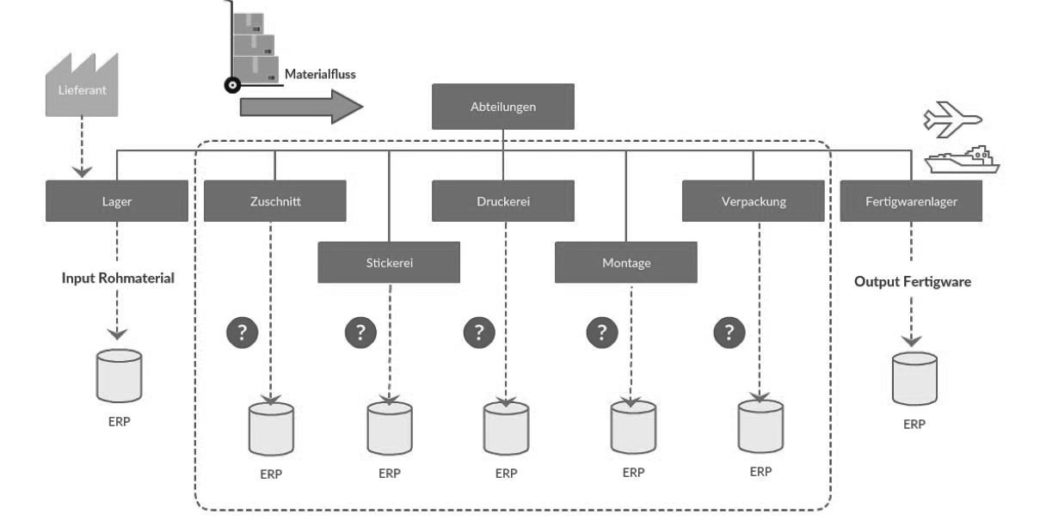

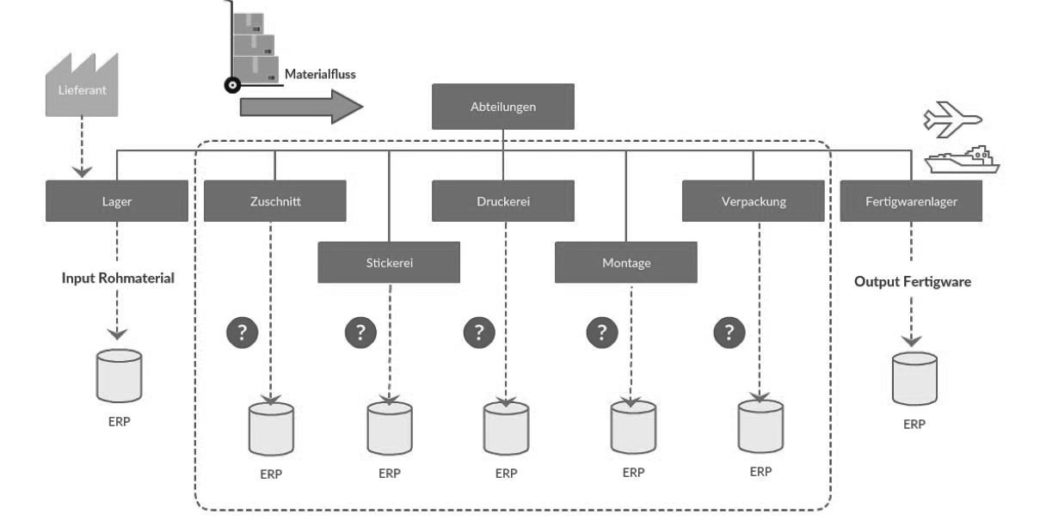

The locations of the departments of A&R Manufacturing (PLC) Ltd. in Sri Lanka and the different production stages:

- Incoming and outgoing goods

- Incoming goods inspection

- Storage

- Cutting

- Stitching and printing

- Welding

- Foam forming

- Sewing

- Packaging

- Administration